For over 50 years, Burlington Safety Laboratory has been a leader in the distribution, calibration, and repair of electrical safety equipment and supplies. We are a NAIL for PET accredited laboratory whose calibration and repair services include rigorous testing procedures that meet or exceed ASTM/ANSI, NFPA 70E and CAL OSHA standards.

At Burlington Safety Laboratory, we provide a wide range of calibration and repair services, including equipment calibration, hot-line and grounding tool repairs, and fiberglass refurbishing. Our ASTM-compliant processes and testing procedures ensure that your essential electrical equipment will reach its optimal accuracy, safety, and longevity. In addition to these in-house services, we distribute safety equipment and supplies designed for both electrical and personal use. For more information about these products and services, contact our team today.

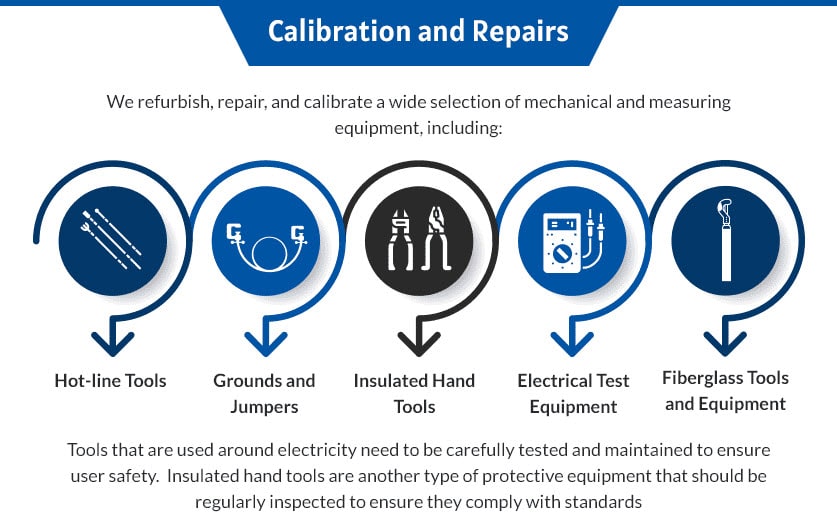

Electrical Test Equipment Calibration

Electrical Test Equipment Calibration

Workers in the electrical industry face a dangerous environment with several potential safety hazards. To mitigate the risks associated with performing essential electrical duties, we offer electrical test equipment calibration services for products like phasing meters and voltage detectors. These services include complete testing procedures such as visual inspection and electrical testing to all applicable ASTM standards.

Electrical test equipment calibration can protect workers from many workplace hazards, including arc flash and electrical shock. It also ensures that your instruments are providing correct frequency measurements, which prevents costly mistakes and ensures the highest degree of accuracy possible.

Insulated Hand Tool Calibration

Insulated Hand Tool Calibration

Having properly insulated hand tools is crucial when working on electrical equipment. The ASTM F1505 standard dictates that electrical hand tools must be able to withstand up to 1000V ac or 1500V dc. Insulated screwdrivers, cutters, pliers, and more provide an extra layer of protection against unexpected electrical currents, preventing dangerous shocks far better than plastic tools with a basic rubber cover. Burlington Safety Laboratory provides testing services for insulated hand tools to ensure optimal protection against hazardous and unpredictable situations.

Hot-Line Tool Repairs

Hot-Line Tool Repairs

Hot-line tools provide protection between electrical workers and live wires, making it especially important to perform regular inspections and repairs on these components. Our hot-line tool repair services include inspecting for any damages, removal of loose material, and checking for proper operation. We can also perform electrical testing to meet ASTM requirements. For tools that warrant more in-depth inspection or specific repairs, we offer a wide selection of replacement parts as well complete refurbishing services.

Grounds and Jumpers Repairs

Grounds and Jumpers Repairs

Even the most routine use cases can damage grounding equipment over time. Regular testing, checkups, and repairs ensure that your grounds and jumpers will maintain their quality and reach their maximum longevity. Our comprehensive, ASTM-approved testing, repair, and refurbishing services offer a reliable way to keep up with the wear and tear that your equipment may experience in the field. From clamps to ground sets, we can service all of your grounding electrical equipment.

Fiberglass Tool & Equipment Refurbishing

Fiberglass Tool & Equipment Refurbishing

Fiberglass tools and equipment are used in various high voltage line work. Over time, they can get scuffed or damaged, making them potential safety hazards. To minimize further damage, maintain their protective properties, and reduce refinished costs, fiberglass should be properly stored, protected, waxed, inspected, and cleaned. At Burlington Safety Laboratory, we offer repair and refurbishing services for a wide range of fiberglass tools, including hot sticks, hot arms, hot ladders, and platforms. Every service performed meets or exceeds ASTM standards.