We are thrilled to share some exciting news from Burlington Safety Laboratory! As part of our ongoing commitment to excellence and safety in electrical testing, we have recently expanded into a new, state-of-the-art industrial facility. This move marks a significant Read More

Category: Electrical Safety Testing

Lab Testing of Rubber Gloves and Products

Rubber is a common material valued for its versatility and durability, but it can degrade over time. Factors that influence the integrity of rubber products include regular use, environmental changes, improper storage, exposure to sharp objects and dirt, and contact Read More

New EBooks Explain the Dielectric Testing Processes Provided by Burlington Safety Laboratory

Did you ever wonder what happens to your personal electrical safety equipment after it is sent to us for testing? Well, now you can read about all the steps we take when testing every personal electrical safety product in 8 Read More

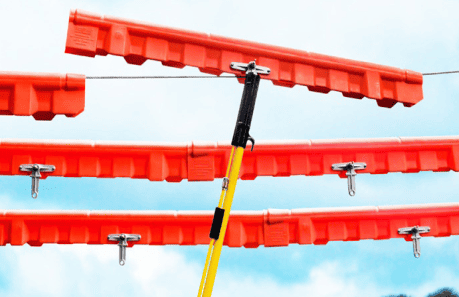

ASTM F712

Introduction to ASTM F712 & Initial Testing ASTM F712 covers the standard test methods and specifications for electrically insulating plastic guard equipment for the protection of workers. However, a notable aspect of F712 is its exemption from requiring initial testing Read More

What Is The Purpose Of Dielectric Testing?

Dielectric Testing Process Here are the basic steps involved in the dielectric testing process: Check-in Removing previous testing marking Washing using cleaning agents that will not degrade the insulating properties Visual inspection of all surfaces (inside and out) Electrical testing Read More