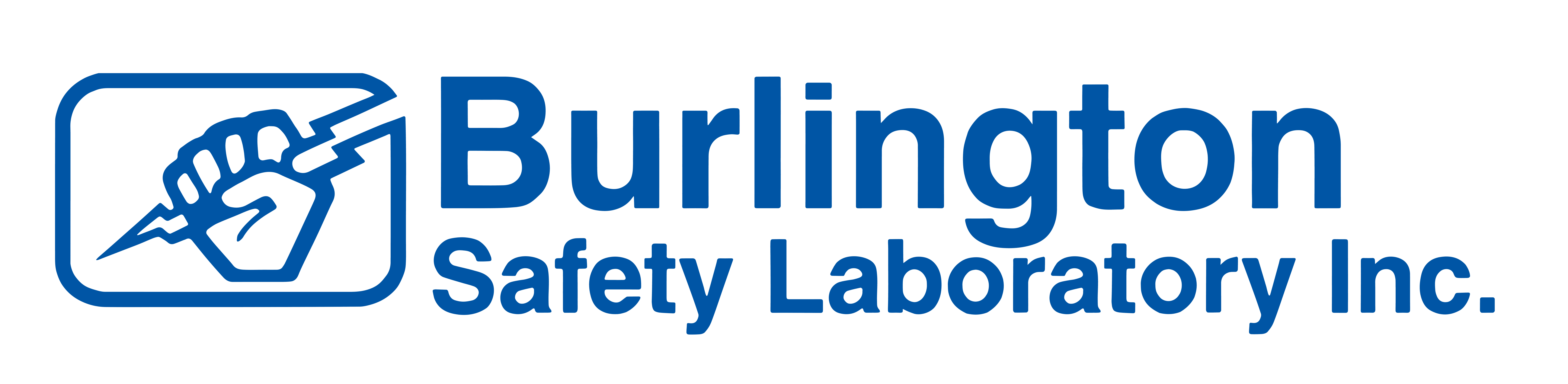

We are excited to announce the opening of a second facility in Southern California next to our Westminster location that is dedicated to dielectric testing, repairs, and part replacements for High Voltage Grounding Sets including Grounding Cables and Insulated Jumpers. The dedication to grounding sets allowed us the opportunity to optimize the floorplan for improved workspaces, warehousing, and overall improved efficiencies to stay ahead of demand.

We are excited to announce the opening of a second facility in Southern California next to our Westminster location that is dedicated to dielectric testing, repairs, and part replacements for High Voltage Grounding Sets including Grounding Cables and Insulated Jumpers. The dedication to grounding sets allowed us the opportunity to optimize the floorplan for improved workspaces, warehousing, and overall improved efficiencies to stay ahead of demand.

Burlington Safety Laboratory has a short 2 week turnaround upon receiving electrical safety grounding cables & insulated jumpers for laboratory testing to ASTM standards. Customers can either ship their grounding sets to us or drop them off at our facility for testing. Upon receiving, our testing process consists of:

- Hand Washing each grounding cable and insulated jumper. This step ensures that every cable and clamp is thoroughly cleaned, restoring them to a pristine condition and ensuring optimal visual inspection.

- Dielectric Testing involves immersing the cables in a barrel of water. The clamps are securely attached to a metal rod positioned above the barrel. Subsequently, the metal rod receives the appropriate voltage required for testing. This setup allows for the assessment of the cables’ insulation properties and their ability to withstand electrical stress. Following the completion of the test, further steps are undertaken to ensure the integrity and safety of the cables. It is important to clarify that we perform dielectric testing on the jacketing of jumper cables, not grounding cables.

- Visual Inspection where each cable and clamp is individually examined for any signs of damage, wear, or defects. If any clamps require repair or replacement, new clamp parts can be seamlessly added to the cable that has just completed dielectric testing. However, if a cable fails the dielectric test and exhibits significant damage or compromise, it cannot be repaired and must be replaced to ensure safety and compliance with standards.

- Optional Part Replacement is performed when our technicians assess the condition of the clamps and determine if replacement or repair is necessary. Clamps can be replaced or repaired for an additional cost, covering all parts of the clamp. Whether a clamp requires a complete replacement or just a specific part, such as a missing screw, can be addressed accordingly. However, it’s important to note that rubber components cannot be repaired or replaced due to their integral role in ensuring insulation integrity.

- Sticker Certification is performed by our technicians who affix a certification sticker to each grounding cable and insulated jumper. This sticker includes a unique serial number, the date of testing, and the location where the testing was conducted.

REMEMBER: High Voltage Grounding Sets, Cables, and Clamps need to be tested every 12 months.

Burlington Safety Laboratory has been testing protective equipment since 1971. We are accredited by NAIL for PET, and our test procedures meet or exceed ASTM/ANSI, MIL Specs, NFPA 70E, FED and CAL OSHA standards. Our quality control procedures include thorough and accurate records of each and every article tested, along with dates and test values. Burlington Safety Laboratory’s technicians are fully trained before they perform critical tests on your personal protective equipment.

Contact Us today to schedule service for your high voltage grounding sets