Arc flash occurs when electric current deviates from its intended route, moving through the air instead of conductor-to-conductor. Workers in hazardous electrical settings need reliable personal protective equipment (PPE) most commonly known as Arc Flash Clothing to keep them safe from heat, fire, and arc-related injuries. Burlington Safety Laboratory supplies high-performance arc flash clothing for a variety of applications and industries.

What Is Arc Flash Rated Clothing?

Arc flash rated clothing for electricians mitigates the danger from arc flash, and complies with Occupational Safety and Health Administration (OSHA) requirements and the following industry standards to protect wearers from multiple types of heat-related threats:

Arc flash rated clothing for electricians mitigates the danger from arc flash, and complies with Occupational Safety and Health Administration (OSHA) requirements and the following industry standards to protect wearers from multiple types of heat-related threats:

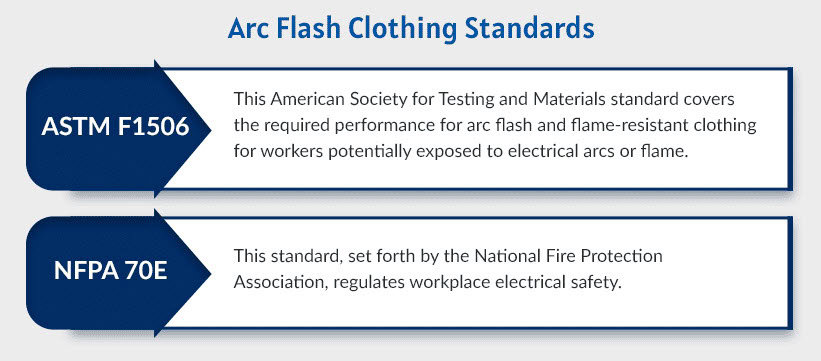

- ASTM F1506 – This American Society for Testing and Materials standard covers the required performance for arc flash and flame-resistant clothing for workers potentially exposed to electrical arcs or flame.

- NFPA 70E – This standard, set forth by the National Fire Protection Association, regulates workplace electrical safety.

Both arc flashes and arc blast explosions can seriously injure or even kill unprotected employees. Protective clothing can insulate workers from harm by acting as a barrier against direct contact with electrical arcs.

Arc Flash Clothing vs. Flame-Resistant Clothing

Flame-resistant clothing also helps protect workers by reducing the severity of injuries, but it’s not the same as arc flash clothing. Electrical arc flash clothing and flame-resistant clothing provide two different tiers of protection. All arc flash protection clothing is rated to be flame-resistant. However, not all flame-resistant clothing offers reliable protection against arc flash.

To be considered Flame-Resistant, clothing must protect wearers from embers, open flame, or flash fires. It should not melt in the presence of heat, but instead act as thermal insulation against it. Flame-resistant fabrics should be able to self-extinguish if they catch fire or resist igniting altogether. To receive the flame-resistant distinction, manufacturers must thoroughly test the clothing to receive a rating based on the level of protection the fabric provides.

Arc Flash Clothing is an even higher distinction. It must meet all the standards of fire-resistant clothing, while also offering protection against live electricity and second-degree burns. Most electrical occupations require workers to wear arc flash clothing whenever they’re near components carrying 600V of energy or more. Manufacturers measure how much energy from repeated arc flashes the textiles can safeguard against before the wearer would receive second-degree burns to establish the tier or quality of the arc flash clothing.

Arc Flash Clothing Kits and Categories

At Burlington Safety Laboratory, we provide safety gear for extreme work environments that pose a fire and electrical risk to workers. The manufacturers use Nomex® thread and meet ASTM F1506 and NFPA 70E standards. Some of the safety products we provide include:

At Burlington Safety Laboratory, we provide safety gear for extreme work environments that pose a fire and electrical risk to workers. The manufacturers use Nomex® thread and meet ASTM F1506 and NFPA 70E standards. Some of the safety products we provide include:

- Arc flash protection face shields – Each arc flash protection clothing kit includes a flame-resistant hood, safety glasses, and a convenient storage bag.

- Arc flash protection coats – Our coats use high-temperature plastic zippers, have expansion backs for added comfort, and are available in a variety of sizes, colors, and arc thermal protective value (APTV) ratings.

- Arc flash protection coveralls – Our coveralls provide full-body protection with set-in sleeves and are available in a wide range of sizes and APTV ratings.

- Arc flash protection jackets and overpants – These products meet applicable safety standards and come in many sizes in stock, with additional options available by special order.

- Flame-resistant sweatshirts – Our regular or UltraSoft® sweatshirts offer flame resistance for work environments with potential employee exposure to flame and intense heat.

- Flame-resistant head protection shielding and hoods – Protect your workers with UltraSoft® knit balaclavas and protective headwear.

Applications and Industries for Arc Flash Clothing

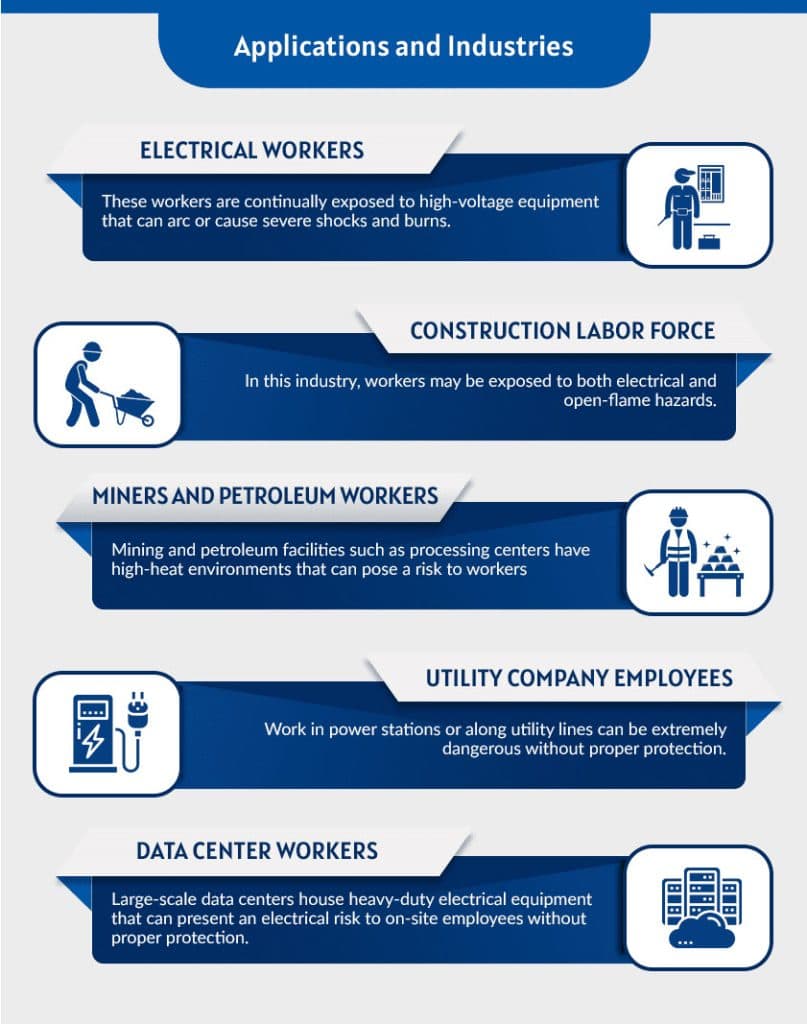

Workers in any environment where arc, flame, and heat hazards are present should wear arc flash safety clothing or flame-resistant shielding. Some of the applications and industries for which we supply protective gear include:

- Electrical workers – These workers are continually exposed to high-voltage equipment that can arc or cause severe shocks and burns.

- Construction labor force – In this industry, workers may be exposed to both electrical and open-flame hazards.

- Miners and petroleum workers – Mining and petroleum facilities such as processing centers have high-heat environments that can pose a risk to workers.

- Utility company employees – Work in power stations or along utility lines can be extremely dangerous without proper protection.

- Data center workers – Large-scale data centers house heavy-duty electrical equipment that can present an electrical risk to on-site employees without proper protection.

What PPE is Required for Arc Flash?

Arc flash clothing protects the wearer by providing a barrier against heat and flames. It maximizes overall protection and minimizes burn injury risk, giving the wearer extra time to escape the fire or secondary explosions. By protecting against burns, this flame-resistant clothing increases survival rates while reducing the need for medical treatment such as skin grafts and the likelihood of infections.

While arc flash PPE kits are not intended as firefighting gear, electrical workers wear them to protect themselves from serious injury due to arc flash and explosions. As a result, PPE plays a vital role in preserving the electrical worker’s quality of life if they are exposed to an arc flash accident.

Even when components are not energized, arc flash can occur at any time and can cause severe injury or death. NFPA 70E requires electrical workers within the flash protection boundary to wear arc flash clothing and have an understanding of arc flash protective clothing requirements. Inadequate arc flash clothing puts workers at risk of serious injury, while excessive levels of arc flash clothing can restrict movement and vision, which can increase accident risk, work time, and work difficulty.

To have optimal protection, workers must wear arc flash clothing that complies with NFPA 70E. NFPA 70E classifies five levels of arc flash risk and assigns a level of protection based on the incident energy in calories. It ranges from Category 0—with an incident energy of 2 calories or less—to Category 4, which has an incident energy level of 25 to 40 calories or more. The degree of protection and number of layers required increases according to the category.

The Importance of Arc Flash Clothing

Arc flash results from one or more faulty bus bars quickly releasing energy, causing a blinding light and burst of heat that can reach up to 35,000 °F. When a current departs from its normal pathway, it can ionize the surrounding air, which turns from an insulator to a conductor. As a result, the energy released from the bus bars can lead to an explosion.

Energy from the explosion gets transferred to nearby surfaces, such as workers’ clothing and skin. Therefore, working on or around energized and potentially energized equipment can expose workers to dangerous arc flash and electrocution. Wearing the appropriate PPE is their last line of defense.

Arc Flash and Flame-Resistant Clothing at Burlington Safety Laboratory

Burlington Safety Laboratory has specialized in protective gear for electrical and high-heat environments since 1971. We’re a leading distributor of arc flash clothing, flame-resistant equipment, and other items for customers in the utilities, telecommunications, railroad, power generation, and other industrial sectors.

We keep a vast inventory of electrical safety and rubber protective equipment in stock and ready to ship from our three U.S. locations. Contact us today to learn more about our innovative arc flash clothing and kits, or browse through our online catalog to start your order.