Linemen require the proper materials to protect them from hazardous electrical conditions that could otherwise cause serious injury or death. Electrical insulating blankets serve as a type of barrier used to protect linemen from accidental contact with live components during energized line maintenance. The flexibility of these blankets enables them to be easily wrapped or folded around irregularly shaped components such as switchgear and transformers, thus providing adequate protection for workers.

What is An Electrical Insulating Blanket?

Electrical rubber insulating blankets, also referred to as shock protection blankets, are used to cover energized components to protect linemen from various electrical hazards. More specifically, they serve as a cover-up for electrical equipment found in substations, switchboards, and cubicles. These blankets are available in various sizes, types, and classes, and they typically have eyelets that allow them to be easily secured using straps, buttons, or pins.

Importance of Electrical Insulating Blankets

The importance of electrical insulating rubber blankets for linemen comes mainly from their ability to protect workers from dangerous conditions. Every year in the United States, dozens of linemen are seriously injured or killed because of high voltage-related accidents. To prevent this, it’s important to implement safe work procedures and use personal protective equipment (PPE) designed to lower the risk of exposure for linemen.

The importance of electrical insulating rubber blankets for linemen comes mainly from their ability to protect workers from dangerous conditions. Every year in the United States, dozens of linemen are seriously injured or killed because of high voltage-related accidents. To prevent this, it’s important to implement safe work procedures and use personal protective equipment (PPE) designed to lower the risk of exposure for linemen.

In instances where a lineman must be closer than the safe distance to energized components, it’s crucial that all energized electrical conductors be insulated from other conductive objects as well as the worker. In these situations, using electrical insulating blankets to cover exposed live parts can prevent injury and death by protecting linemen from electrical shocks and accidents.

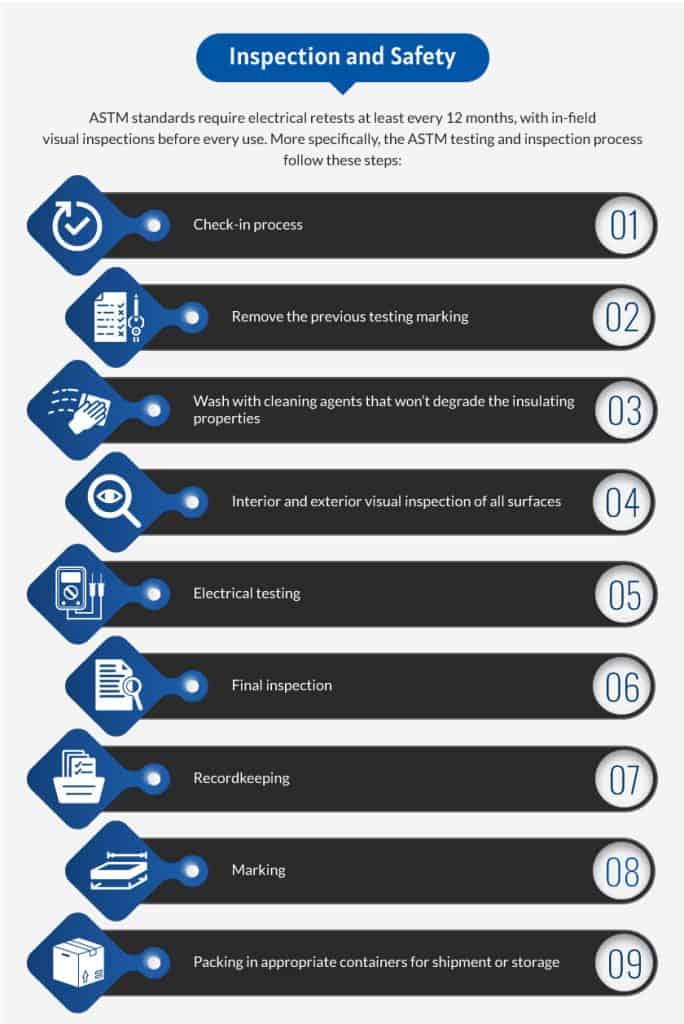

Inspection and Safety

To ensure optimal performance and safety, electrical insulating blankets must be properly inspected before use. It’s important to roll blankets to check for age-cracking, corona cutting, snags, abrasions, tears, and scratches. They should be rolled at least two times on each side, with the second roll perpendicular to the first. Any blankets that show signs of damage should be removed from service.

ASTM standards require electrical retests at least every 12 months, with in-field visual inspections at least every six months. More specifically, the ASTM testing and inspection process follow these steps:

- Check-in process

- Remove the previous testing marking

- Wash with cleaning agents that won’t degrade the insulating properties

- Interior and exterior visual inspection of all surfaces

- Electrical testing

- Final inspection

- Recordkeeping

- Marking

- Packing in appropriate containers for shipment or storage

Electrical Insulating Blankets from Burlington Safety Laboratory

Linemen are regularly exposed to energized components that, without the proper protection, can cause serious harm to workers. To ensure the safety of linemen, electrical insulating blankets can be used to cover hazardous live parts.

At Burlington Safety Laboratory, we are a go-to source for linemen’s protective equipment. As part of our offerings, we provide top-quality electrical insulating blankets designed to create a barrier between workers and energized electrical components. Depending on your particular needs, we can deliver protective blankets in a wide range of styles and sizes to ensure optimal protection. For more information about our shock-protection blankets and other electrical safety equipment, contact Burlington Safety Laboratory today.